This morning, while starting a new weaving project on my rigid heddle loom, I realized that I have neglected to write about some of my earlier projects. Over the past two years, I have woven dozens of scarves, most of which I have given as gifts or donated to various charities. For these scarves I generally used the plain weave technique. This is the technique that we all learned in school , the over one / under one weaving style. Made with fun yarns, this technique can make for a lovely scarf.

About a year ago, I tried out a new weaving technique that is really fun to do. Looking more complicated than it really is, clasped weft weaving utilizes the interlocking technique commonly used in tapestry weaving.

For those that do not weave, a brief description of terms. When weaving, there are two components to creating the cloth – warp and weft. The warp threads run lengthwise through the project and are held on the loom under tension during weaving. When woven on a loom, the weft threads run side to side and are inserted, or “thrown”, by the weaver. The resulting cloth is created by the interlacing of the warp and weft where both directions of threads are visible. When doing picture or landscape tapestry weaving the weft threads may change mid shed, the threads are wrapped around one another, or clasped, to avoid having a hole in the cloth.

On a loom, clasped weft technique involves two weft threads that are visually different. This can be two different colors, or shiny vs matte, etc. The basic idea is that one weft goes through the shed, wraps around the second weft and then pulls the second weft into the shed. This results in a weft that is doubled in each shed. The pattern created by the interlocking of the weft can be either planned out or random.

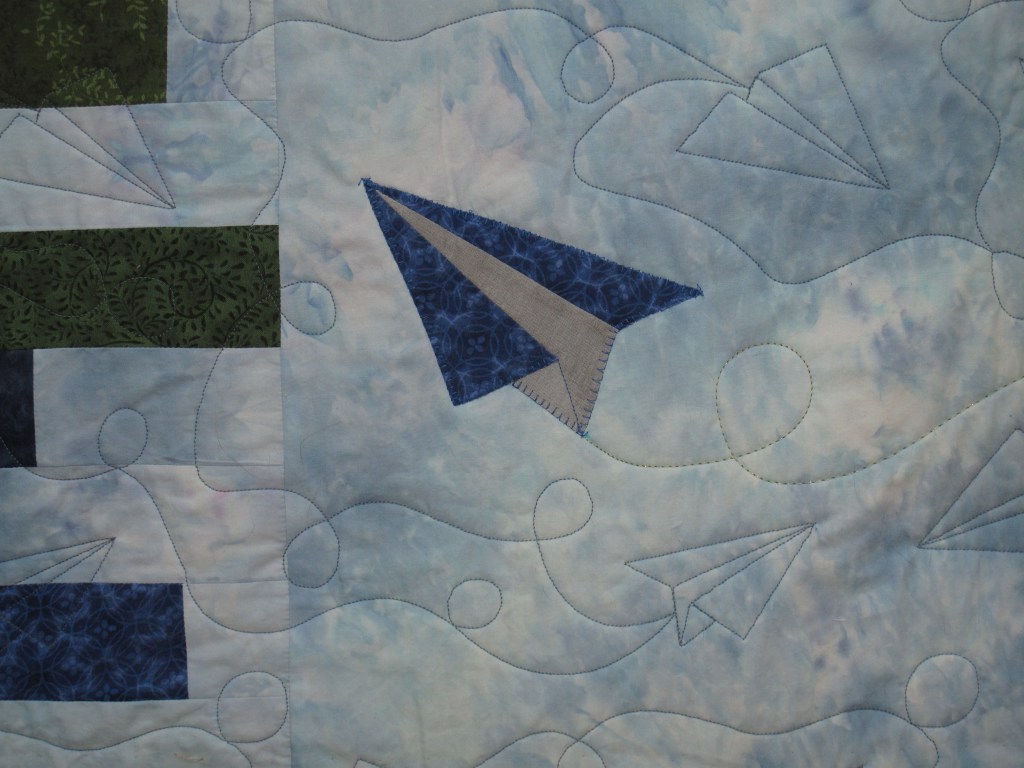

The picture above shows a wall hanging that I made for our guest room. This project was planned out to give an very even design in the clasped weft fabric.

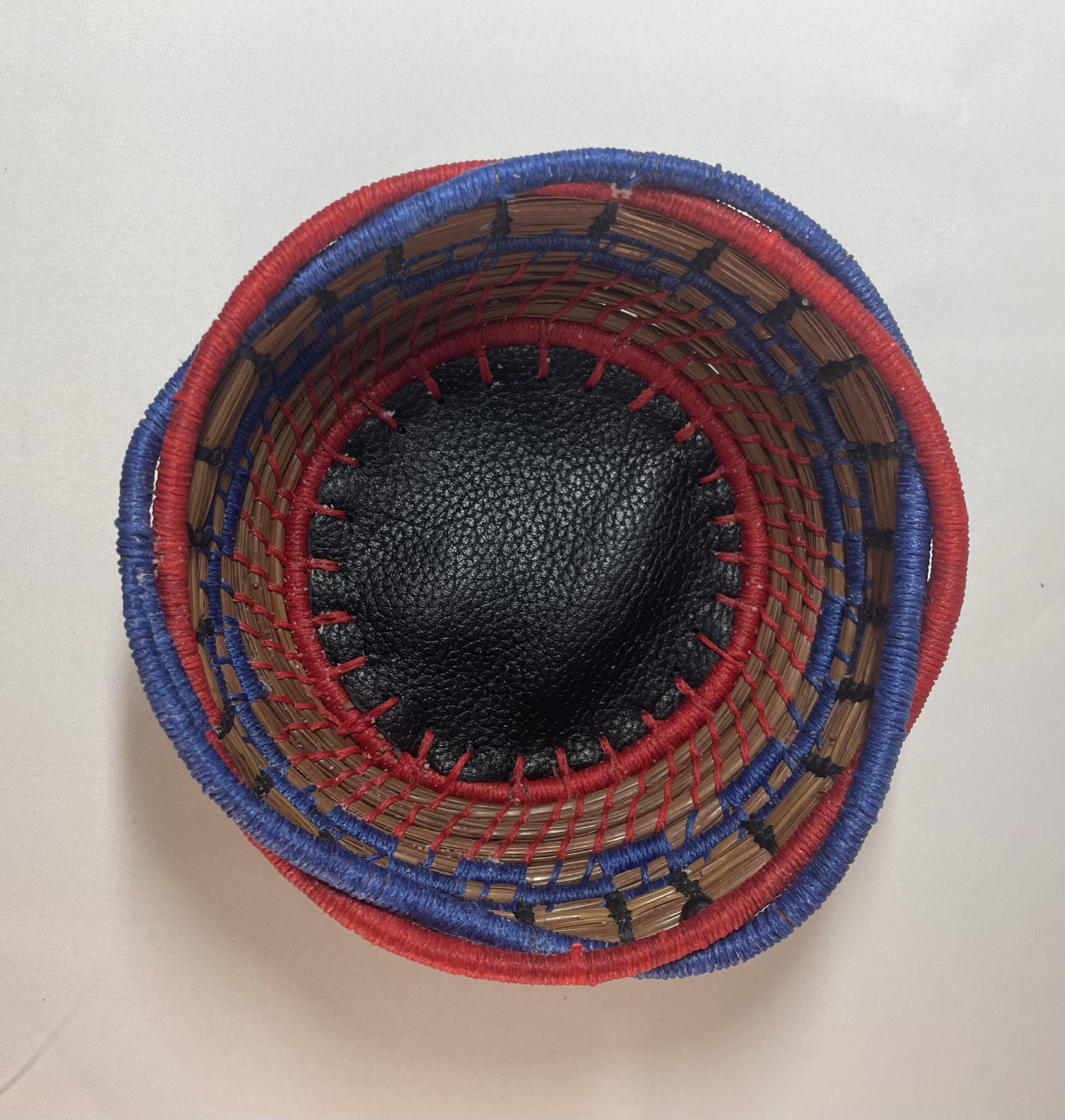

This picture shows a scarf that I made that was a random interlock of the clasp weft. Combined with the variegated yarns, that complemented each other well, the result was a much more organic design.

This morning I started playing with an idea I had that involved a planned out pattern similar to the wall hanging. However, instead of just doing two colors, I opted to do alternating shed from either side to create an argyle looking design. Each shed included one weft yarn that was the same. I really like how it looks so far and look forward to finishing this scarf. After I finish this scarf, I think I will try another scarf where the colors of the sheds are all different to see what other fun designs will result.