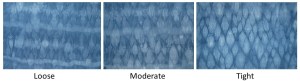

When writing about my latest Shibori project, I alluded to some sun dyeing I had attempted. After that first attempt, I decided to do some experimenting to determine the best protocol to use for sun resist dyeing.

The idea behind sun resist dyeing is that objects placed on the wet soy-treated fabric will block the suns rays from activating the soy binding of the dye to the fabric.

Having read several different articles about dyeing with soymilk, I first wanted to compare the different ways of prepping the fabric and dyeing the fabric. Some textile artists use just soy milk, some use powder from soybeans and other use soda ash as a pretreatment. So I set up to test several different combinations of pretreatment and dyeing.

For pretreatment, I used used three old pieces of partially dyed fabric (browns and khaki dyes). Each piece was pretreated with either soy milk (1 cup diluted with 3 cups water), soy powder (1/4 cup powder diluted with 4 cups hot water), or soda ash (4 tsp each of soda ash and salt, diluted in 4 cups hot water).

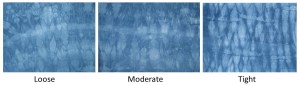

Based upon these test samples, pretreatment of the fabric with soy powder did not result in very strong binding of the blue dye to the fabric. Furthermore, mixing the dye with soy powder did not result in any binding of the blue dye to the fabric. Pretreatment with either soy milk or soda ash was successful in dye binding. However, only the mixing the dye with soy milk cause the sun resist to be visible.

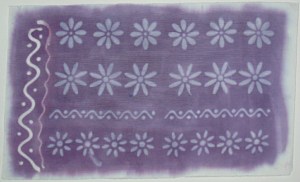

I did a second round of experimenting to verify my findings. In this experiment, the fabric was pretreated with soy milk (left side) or soda ash (right side) and dyed with three different colors of dye (Golden Yellow, Fuschia and Mixing Red) mixed with soymilk.

I love the results! I can’t wait to do more sun resist dyeing.

Free time is hard to find now that I am back to work. However, while my office was closed down in the spring, I had lots of extra time available. One of the things I did during my time off was to work on some fabric dyeing ideas.One bright sunny day, I set up some sun dyeing on my deck. I had seen this technique on a different blog (

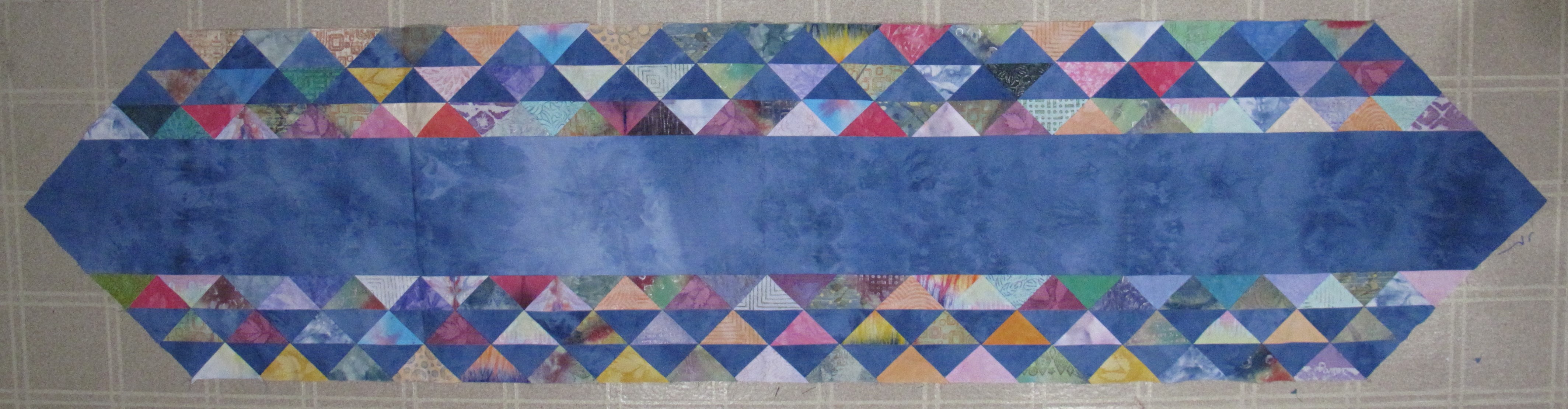

Free time is hard to find now that I am back to work. However, while my office was closed down in the spring, I had lots of extra time available. One of the things I did during my time off was to work on some fabric dyeing ideas.One bright sunny day, I set up some sun dyeing on my deck. I had seen this technique on a different blog ( Rather than just stashing the dyed fabric away to use whenever inspiration hit, the next day I decided to work on an idea that I had for a Shibori quilt.Last summer, I posted about a

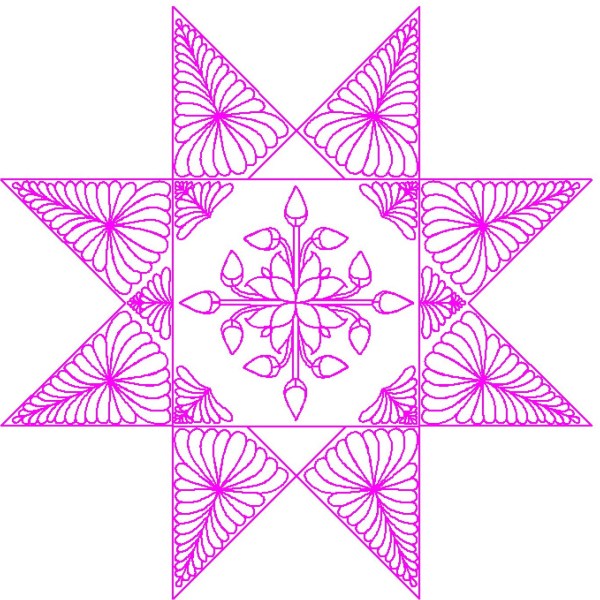

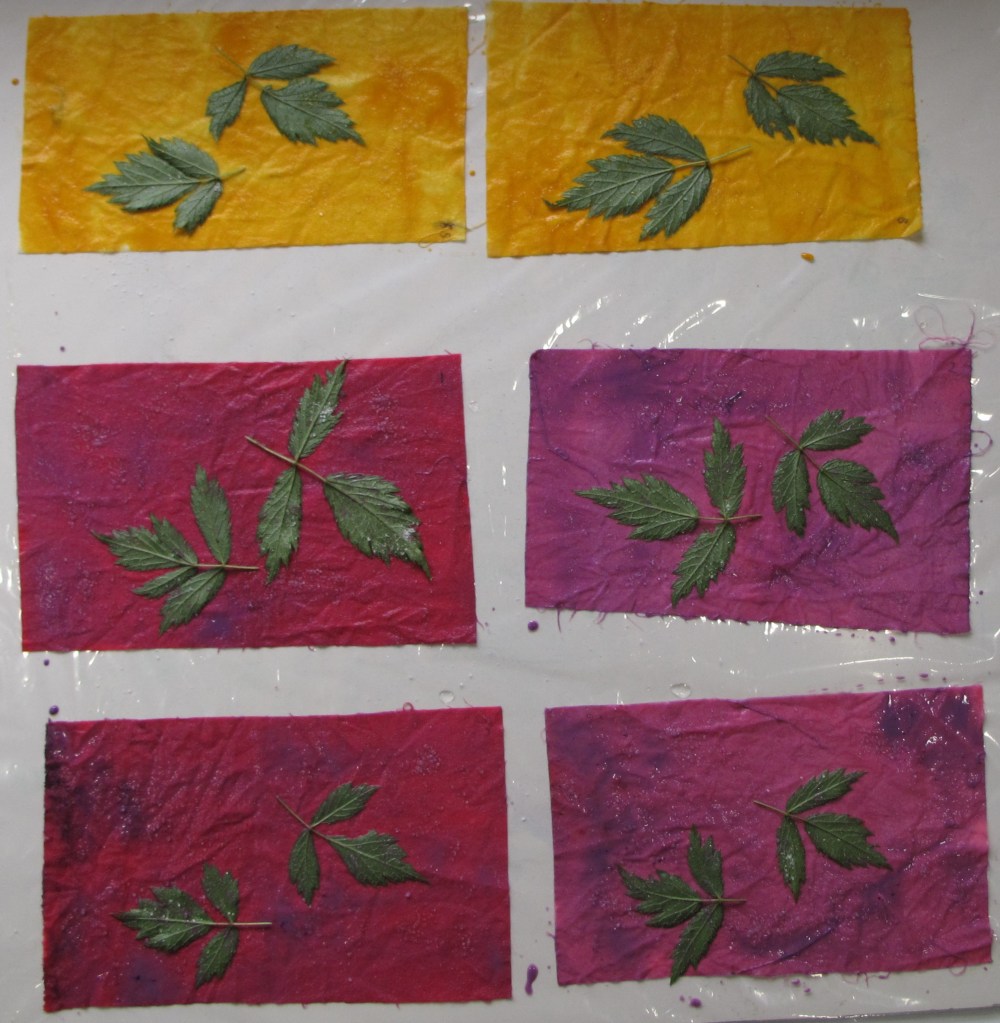

Rather than just stashing the dyed fabric away to use whenever inspiration hit, the next day I decided to work on an idea that I had for a Shibori quilt.Last summer, I posted about a  The Green leaves were painted.

The Green leaves were painted. The threads were gathered and tied tight.

The threads were gathered and tied tight. And the background was dyed blue.

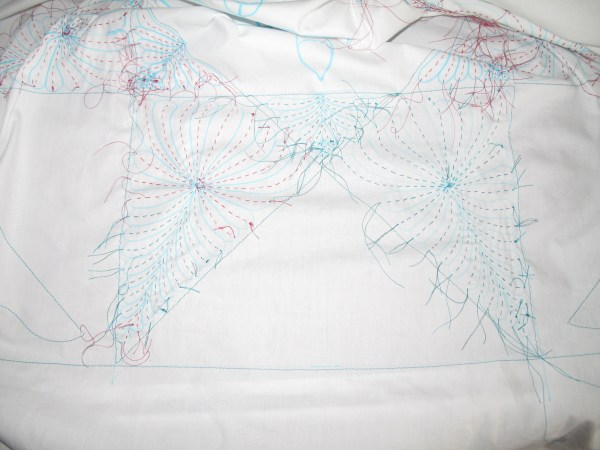

And the background was dyed blue. This project sat in my sewing room for a few weeks. Now, after a couple hours of long arm quilting and I am finally done with this project.

This project sat in my sewing room for a few weeks. Now, after a couple hours of long arm quilting and I am finally done with this project.