Last year, I took a trip to Colorado to see the fall colors in the Rocky Mountains with one of my sons. Unfortunately, we were about a week too late – while the scenery was still beautiful, we dealt with snow and cold.

This year we decided to do our fall color drive about ten days earlier. The fall colors were lovely, as was the weather. The day that I arrived in CO was cold and rainy, so after having a tasty dinner at Sauce on the Blue in Silverthorne, we drove to our villa in Vail. The next day, after waiting for the weather to clear, we left around noon and drove Buffalo Pass through the Medicine Bow and Routt National Forests. On day two, we drove the Top of the Rockies National Scenic Byway. This drive took us from Leadville, over Independence Pass to Aspen for a late lunch. On our third day, we drove the Grand Mesa Scenic Byway and continued south to Ouray, CO. Here we found the Box Canon Park, a mineral hot springs that is tapped and piped to the city pool. On our last day, leaving the mountains, we drove Guanella Pass before I needed to head to the airport and return home to MN. It was a lovely trip enjoying time with my son and God’s wonderful creation.

Last Friday, October 14th, we awoke to snow falling in MN. While it was lovely to see, I was not quite ready for “winter” weather.

Later that day, I left for a weekend getaway to Gull Lake with a few friends. What a wonderful time of conversation (and CE) we had.

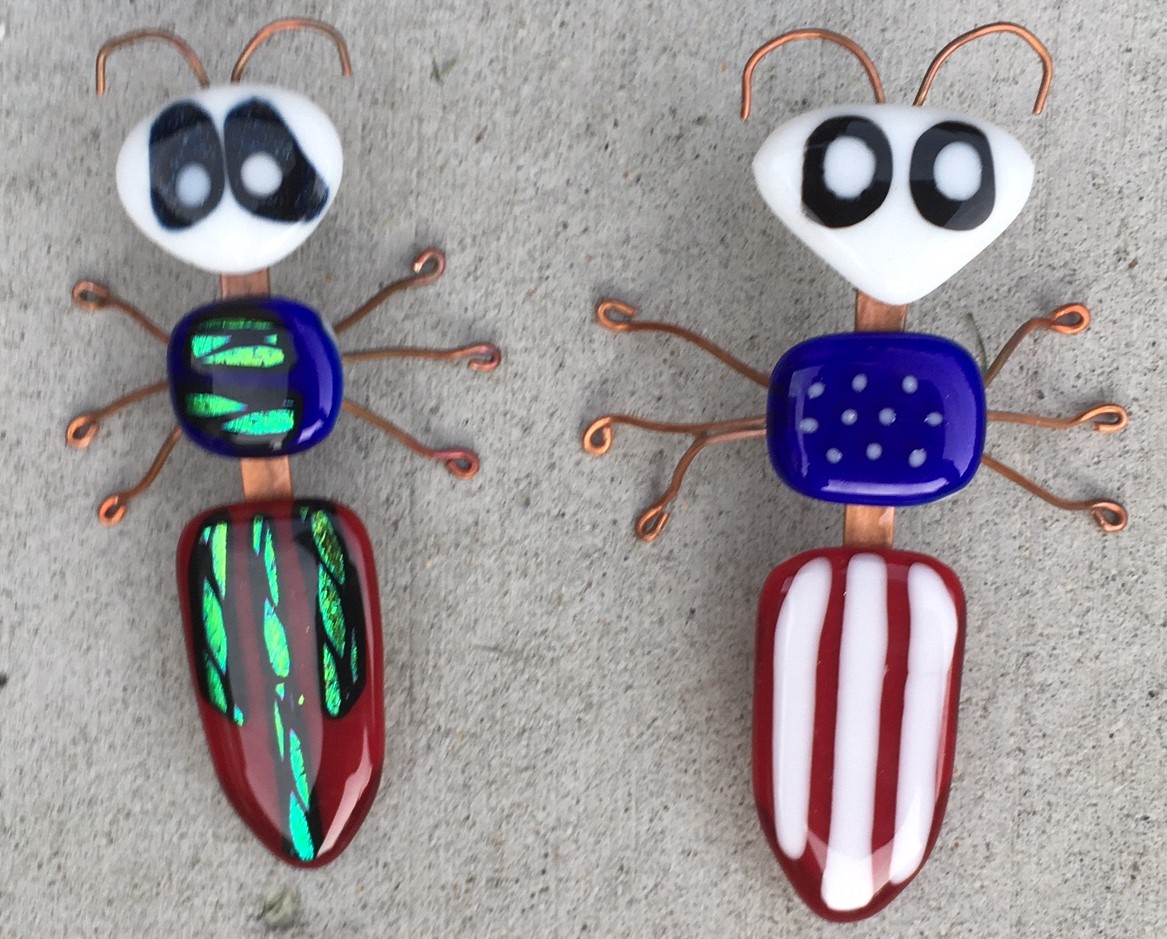

Since I am writing about fall, I am including a couple glass projects that I completed this year.

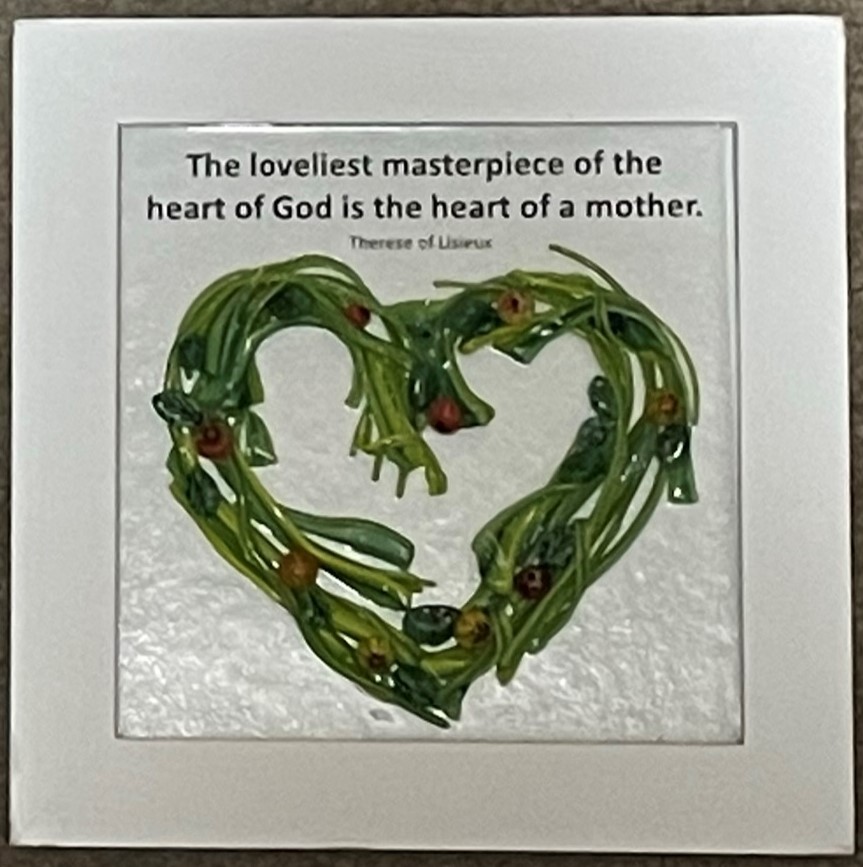

Napkin Holder – made with twisted copper wire, sheet glass and leaf shaped murrini.

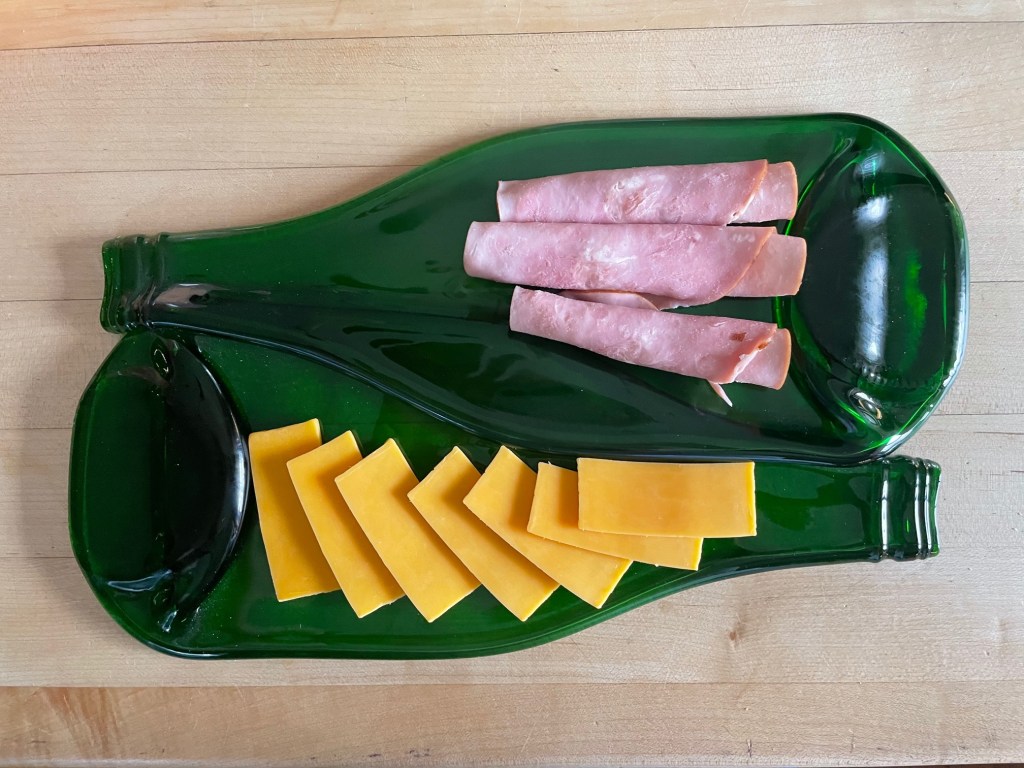

Dessert Plates – made with copper Mica, iridized glass cut into shapes of leaves and glass frit.

Tree Votive Holder – made with glass strips / coarse frit slumped over a metal votive form

Wishing everyone a Happy Fall!